“Local” Is Way Harder Than You Think

Tim Piersant and his partners had to unite the people of Chattanooga to reverse Prohibition-era laws before they could even begin their quest to start making whiskey in a city that long ago turned out more booze than any other place in Tennessee. As it turned out, changing the law was the easy part.

“Would you drink Chattanooga Whiskey?”

That’s how the company known as Chattanooga Whiskey started in 2011: a random question about a nonexistent product posted on Facebook, which resulted in more than 2,000 likes by the end of a month’s time.

Chattanooga was thirsty for some whiskey. Tim Piersant and Joe Ledbetter were just the men to bring it to them. But there was one small problem: It was against the law to make it in the midsize city in southeastern Tennessee.

So the duo outsourced an aged, well-rounded bourbon from Midwest Grain Products/ Lawrenceburg Distillers Indiana (MGP) – one of the largest contract distilleries in the country – and began bottling Chattanooga 1816 Reserve and 1816 Cask. The “1816” was in honor of the year in which Chief John Ross founded the trading post, Ross’s Landing, which would eventually become Chattanooga.

In the booming distilling business, young liquor companies often fib about where products are made — particularly if they are making spirits that require aging, such as bourbon and other whiskies. As The Daily Beast asked in a story last year, “How do you open a distillery one year and have 5- or 15-year-old whiskey to sell the next?” The answer is, you can’t — unless you buy the whiskey you intend to sell from someone who has already aged it.

But Piersant and Ledbetter of Chattanooga Whiskey did something else. They were upfront about where their whiskey was made. They had to be, because it helped make a valid political point: Shouldn’t the stuff called Chattanooga Whiskey actually be made in Chattanooga?

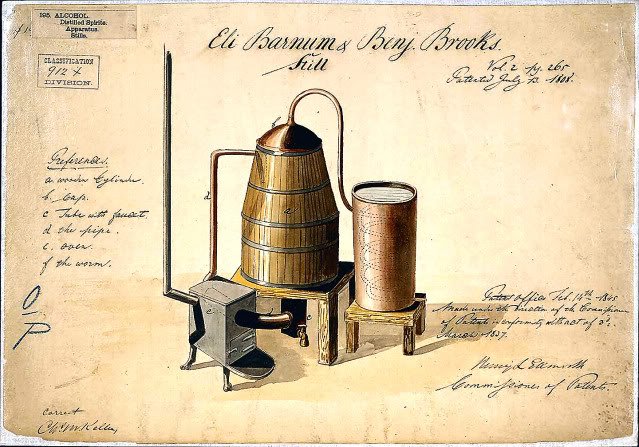

Chattanooga Whiskey's micro-distillery, Tennessee Stillhouse, opened on Market Street in March.

In 1866, not long after the Civil War ended, a man named Elijah Roach Betterton was released from a Union prison camp and moved back down South. He took over his family’s gristmill and a few years later, he opened a small bar in Chattanooga selling whiskey. By the late 1800s, the town had more than 30 distilleries; it was the largest distilling center in the state.

In the early 1900s, a nationwide movement was growing against drinking, making and selling alcohol. The Prohibition Party, the Anti-Saloon League and the Women’s Christian Temperance Union condemned liquor, declaring it was of the devil.

By 1909 Tennessee laws prohibited the sale or consumption of alcohol within a four-mile radius of schools and made it illegal to manufacture it within the state. In 1920, the National Prohibition Act, otherwise known as the Volstead Act, was enacted, making pretty much anything having to do with alcoholic drinks illegal. It was called the “noble experiment.” The experiment, of course, didn’t go over so well. People didn’t quit drinking. They just found sneakier ways to do it. Moonshining rose rapidly, as did the power of gangsters, specifically Al Capone.

Prohibition was repealed in 1933, but Tennessee didn’t repeal its ban on manufacturing alcoholic drinks until 1937. Prohibition, strangely enough, only halted production of Jack Daniel’s and George Dickel’s whiskey for a short time due to a loophole that allowed liquor distillation in three counties in Tennessee – Lincoln, Moore and Coffee. It wasn’t until 2009 that the Tennessee Legislature voted to change the distillation laws in the state, making it legal to produce whiskey and other distilled spirits in 41 counties.

But Hamilton County, of which Chattanooga is the seat, was excluded. And it remained that way for almost 100 years.

That is, until Piersant and Ledbetter started the “Vote Whiskey” campaign, a tool to educate Chattanooga citizens about whiskey and the political process. Their goal was simple: to reverse the law and open a distillery, and eventually move the production of Chattanooga Whiskey to its namesake city.

Chattanooga Whiskey founder Tim Piersant inspects his product.

With no money for lobbyists, Piersant and Ledbetter began a campaign to persuade Chattanoogans to fight the law and get whiskey made in their town once again.

“When we started the company, it was all about telling a story and getting it in a bottle and getting the product out there,” says Piersant. “And then it became about wanting to build a distillery, because we were transparent. We believed in transparency. In this industry, it’s fairly rare — a lot of private labeling, a lot of people not disclosing where their products are made. People think it’s local, and it’s not really local. So Joe and I would go out and make it a point to tell people that our shit is not made here.”

At least, not yet.

Internationally known whiskey writer Chuck Cowdery explains this phenomenon.

“People who sell a product they did not distill are called non-distiller producers, or NDPs,” Cowdery says. “Most small or brand-new NDPs, such as Chattanooga Whiskey, buy bulk from the distiller. They find out what the distiller has in inventory (number of barrels from what recipe at what age) and negotiate a purchase. Bulk is always a standard recipe since the NDP wasn’t in the picture when the whiskey was made. The NDP can choose a bottling proof (how much the whiskey will be diluted with water for bottling), but otherwise has very little opportunity to customize the product. Then they put it in a bottle, label it and sell it.”

He says that some producers, such as Templeton Rye, go to great lengths to create the false impression that they made the product from their own recipe, when they in fact did not.

Piersant feels strongly about the lack of information given to consumers About where the whiskey they buy comes from and how it is distilled. He and Ledbetter wanted to shine a light on the industry. Their passion then got political. Their grassroots campaign addressed more than just transparency in the whiskey industry; it became about transparency in politics.

“The system is mind-blowing,” says Piersant. “I was disappointed at how vaguely the original state law was written and how difficult and unwilling the attorneys general were in trying to comprehend it. That ended up costing a small business a lot of time and money for our own attorneys to communicate our findings. … But if people speak up, then the voice is heard.”

The Chattanooga Whiskey became faces of change. Piersant and Ledbetter used social media, town hall meetings and old-fashioned phone calling to keep the topic of changing Hamilton County’s distilling law in the public eye. They were bringing power to the people.

As word spread, thousands of Chattanoogans, as well as people from around the world, came together to protest the law. And it worked. But the process to change the law wasn’t that simple. Leading up to the county vote, Piersant recalls, he and Ledbetter had met with each one of the county commissioners, asking for their support. On the day of, though they were confident in the support of five commissioners, they needed a supermajority to win, which on the Hamilton County Commission requires six votes. Piersant and Ledbetter weren’t sure if they could get the support they needed from the other lawmakers. But due to the level of public support, the vote came out seven to zero with two abstaining.

The next step was sending the vote to the state, which was a nearly four-month battle. There were opposing lobbying efforts by another distillery fearing competition. And there was one former Chattanooga legislator who had single-handedly held distilling efforts out of Chattanooga in a 2009 bill. Still, Piersant and Ledbetter’s campaign prevailed.

Gov. Bill Haslam signed the bill into law in the spring of 2013.

Inside Chattanooga Whiskey's newly opened Tennessee Stillhouse

To celebrate their victory, the Chattanooga Whiskey founders threw a free block party at the site of what they planned to call Tennessee Stillhouse, where the company said it would build Chattanooga’s first whiskey distillery in almost 100 years. More than 5,000 people swarmed downtown Chattanooga’s Southside district to mark the next step in the story of Chattanooga Whiskey.

Then their plans for the location fell through.

“We started going down one path with one building and we had a victory party where 5,000 people showed up,” Piersant says. “But we couldn’t get it done timely with the owner of the building.”

Piersant and Ledbetter, together with their investors, then found another location in the heart of the downtown tourist district, an historic building that originally housed a used car dealership. It was to be one of the largest urban craft distilleries in America, with a retail shop, a tasting room and a production area for guests to see how whiskey is made. The third floor was where the more than 1,000 barrels of whiskey would have been aged. The company purchased a 30-foot-tall copper column still with the ability to fill four 2,700 gallon fermenters. But after seven months of planning, the costs to convert the old building into a modern whiskey distillery proved to be too much. And so the second location was also abandoned.

“In trying to educate the consumer, we’ve also been trying to educate ourselves on how to build a damn distillery,” Piersant told me when he was regrouping after the second location fell through. “We’ve been learning, and one of the things that has been most eye-opening is what it takes to be a fairly large-scale urban distillery. And when I say urban, I mean lots of zoning and codes, fire codes, and the location (relative) to churches and schools. In the South, there’s a church within 500 feet everywhere. But in this process, we’ve made a lot of great connections to help us understand better, and it’s still a learning process. But we’ve recently figured out exactly how much it costs. And structurally, process-wise, there have been and are some hurdles to overcome. We will get it done. I can say that confidently.”

Then, as if this wasn’t enough, news broke that Ledbetter was out. The co-founder resigned from his position at Chattanooga Whiskey. In his words, according to a news article in Nooga.com, “I’m resigning because, well, I’m really tough to work with.” The trials and tribulations of the whiskey business had taken a toll on him, his family and his relationship with Piersant.

“Having never started a company, let alone one that grew so quickly, I think it would be fair to say that I’ve made a lot of mistakes,” Ledbetter said at the time.

Of his time with Ledbetter, Piersant says, “Joe and I together, creating this was what we did really well, creating this concept and fighting the law and rallying the people around it. All I’ll say is there’s been a lot of surprises in business. Those are rough waters to navigate. The two of us equally struggled with it. Every time we changed locations, it was plastered all over the news.

“By 2014, we had pulled the plug on two locations, cancelled what would have been the city’s largest New Year’s party called ‘The Barrel Drop,’ and then the cofounders split. That was a difficult year after feeling on top of the world. Startups 101: Don’t ever think you’ve arrived.”

Despite Ledbetter’s resignation and the difficulties in finding a permanent home for their distillery, the company has done some growing.

Chattanooga Whiskey has assembled a young and dynamic team with seven full-time employees including an operations manager, marketing strategist, creative director and sales ambassador. The company also employs six part-timers.

“We were very real with ourselves when establishing the brand and making plans to build a distillery and raising capital,” Piersant says. “We have smart investors and when they ask you, ‘Surely you guys aren’t going to run this company long term?’ Joe and I said, ‘No, no, we’re not.’”

Until Chattanooga Whiskey finds another location for its full-scale distillery, Piersant has found another way to get Chattanooga Whiskey into production in Chattanooga, instead of Indiana.

This spring, the company finished construction on a micro-distillery, Tennessee Stillhouse, in Chattanooga’s newly revitalized Southside, and on March 24, it opened to the public. The 3,000-square-foot retail space sits across Market Street from the Chattanooga Choo Choo Hotel, formerly called Terminal Station, built more than a century ago as the city’s main train station. Tennessee Stillhouse has a small bottling line, a tasting bar, a patio for events and merchandise for sale. There is also a 100-gallon copper pot still for experimental purposes.

“So, this is a really dynamic space,” says Piersant. “The experience at 1439 Market Street is going way more than just a storefront. It is an awesome balance of history, retail, production, tasting and aging. We are changing the rules with how people tour distilleries. We have barrels underground and the most elaborate tasting bar I’ve ever seen in any distillery. Large distilleries are great for production, but the experience can be lost in translation if it’s just a bunch of empty space. We absolutely made the right decision to be here.”

The building, which is more than 100 years old, is adjacent to the lot where one of Chattanooga’s first distilleries stood: E.B. Gibson, which was in business from 1903 to 1915.

Piersant also hired Grant McCracken, former head brewer and researcher at Samuel Adams Brewery, as the company’s very first head distiller. He believes that because of McCracken’s strong brewing background, it’s going to be an advantage for his company. After all, whiskey is, essentially, distilled beer.

“You’re seeing people doing some really creative stuff with aging and mash bill (the recipe of various grains that are fermented and then distilled),” Piersant says. “A craft brewer actually has a much tighter process. So the door’s wide open. I’d really love our one and only full-time distiller to have full autonomy and get as creative as he’d like to.”

McCracken, who began his brewing career as a homebrewer before going to Sam Adams, was looking for something new.

“It was just a great opportunity … a new challenge, and to have a startup kind of feel is a really cool change of pace,” he says. “You make all the decisions. It’s all on you, so whether it’s a terrible decision or a great decision, you take ownership of it, which is a beautiful thing. It’s scary but it’s really exciting.”

It wasn’t just the challenge of changing careers from a beer brewer to a whiskey distiller that he was looking for. Though the whiskey distilling process is new to him, that was only part of the equation. He was looking for a good team, one that he knew he could bond with, one with people he could call family.

“The No. 1 thing, I came from a lot of good teams at Boston Beer, so my one non-negotiable (was) it has to be a good team — people I have to really get along with,” McKracken says. “I can’t just leave that behind. The job I am equally passionate about, but to make a real experience, fully what I wanted it, it was all about the team. And these guys just had me head over heels.”

Piersant believes McCracken is worth his weight in whiskey gold.

“He's a mastermind at taking what makes traditional bourbon so great, and creating more of those beautiful aromas with malted grains and beer yeasts,” Piersant says. “Real Chattanooga Whiskey will be ready 2 years from now, and it will represent the best whiskey ever made in Chattanooga pre-prohibition, maybe better. The 1816 recipe will carry on, and will eventually be 100% Chattanooga-made, but our priority is establishing the first couple of Chattanooga mash bills since pre-1915.”

Head Distiller Grant McCracken busy making history.

Wes Phelps, a restaurateur for more than 30 years and a longtime supporter of Chattanooga Whiskey as well as friend to both Piersant and Ledbetter, admits he’s a bit disappointed that the company has gone in a different direction.

“As I got to know Tim and Joe, I realized it was more than just an idea to make money,” Phelps says. “They actually never talked about money or success. They talked about history, Chattanooga history, and how much they love this city. Was I disappointed when the other sites fell through? Yes. Was I disappointed when the John Ross site fell through? Yes. Has this affected their fan base? Yes. The flame has dimmed some; doubt seeps in.… It would be a shame for this history-making idea and movement to end up just being a small storefront on Market.”

Phelps remembers how much of a hold Chattanooga Whiskey had on the town — the momentum and public support the company garnered from constantly pushing their message of “Vote Whiskey” through social media, local newspapers and TV stations.

“It was a wild ride watching Tim and Joe work this town,” Phelps says. “I used to describe them as rock stars, Lennon and McCartney. Everyone knew Joe and Tim! A lot of us got caught up in the excitement that was building.”

After the bill passed to allow whiskey production in Hamilton County, Phelps recalls how shocked and weary the duo was after the announcement. “They had a kind of ‘what just happened?’ feeling. I remember saying, ‘You did it,’ and then it was, ‘Be careful what you wish for.’”

After visiting the newly opened Stillhouse, Phelps says he is impressed with how quaint the space is and how knowledgeable the staff is when it comes to whiskey.

“It’s a great start for the company to get the name out,” he says.

As Piersant reflects on his long journey to bring whiskey-making back to Chattanooga, he admits he and Ledbetter made some mistakes with PR throughout the ordeal. But he believes their intentions were good: to do something amazing.

“It's easy to dream big, and easy to get caught up in being the best, but those two things should not be related,” he says. “The micro-distillery is the perfect combination of experiences. It's the perfect first step for our brand and what we represent.”

The second step will be to build a full-scale whiskey distillery — eventually. Piersant is insistent it will happen, but not right now. Instead of focusing on what Chattanooga Whiskey can bring to the people of Chattanooga in the future, he’s focusing on what it can bring to the people now.

“I think that this space reflects the personality of our company. I think we're a super dynamic, very small packaged company and that's what you're going to get out of this space. It's the perfect place to start before we go next. And I think it took us a very long time with a lot of changes and conversations to realize that.…This company is about making great whiskey, offering a great experience in Chattanooga, and building a fun culture. You can do that with any size operation and be successful.… Am I disappointed things don't work in general exactly the way you envisioned them to work from inception? I wouldn't say I feel disappointment. The emotion is generally frustration and anxiety to live up to your own expectations plus everyone else's around you.”

Between last fall and this March, Chattanooga Whiskey concentrated more on readying the Tennessee Stillhouse micro-distillery and less on staying in the public eye. Even the news promoting the Stillhouse’s grand opening — something that would have at one time garnered a front-page headline — was pushed to an inside section of the local newspaper. Piersant seems less worried about public approval at this point and more worried about getting his micro-distillery off the ground. And as of its opening, Chattanooga Whiskey is finally producing original product in its namesake city.

But after deciding to go with a smaller, storefront location, a question lingers: When will Chattanooga Whiskey begin producing its whiskey on a larger scale in Chattanooga?

McCracken the distiller has only been on the job a few weeks, but when he talks about the future of Chattanooga Whiskey — and his and Piersant’s plans for future products — he talks with the passion of a child who has his whole life ahead of him. And in a way, he does. Both men do. But they are both wise enough to understand how important it is to respect the past.

“One thing we have always spoken about here is changing the rules and at the same time, looking back at tradition and taking the best of what’s been done before,” says McCracken. “You don’t want to look to the past and forget all that was accomplished and forget all the learning, what the hundreds of years of distilling knowledge has come to. We’re at a stage where we want to kind of realize the best of both. For us, as we start to make whiskey here out of this facility, we aren’t going to be be able to replicate 1816 perfectly. We’d drive ourselves crazy.”

The 1816 line’s mash bill is 75 percent corn, 21 percent rye and 4 percent malted barley. The Reserve is 90 proof, while the Cask is 113.6 proof. McCracken says they will continue to use that recipe when they begin producing 1816 in the larger distillery they plan to build. “Overall, we think it will be a good option to carry on this recipe in some form for those who have enjoyed the product for so long,” he says, but he notes that it will be impossible to duplicate the current product’s flavor profile exactly.

“We should be able to come relatively close,” he says. The unknown factors lie in the “terroir” from which his ingredients come. Chattanooga Whiskey is using local, non-GMO corn from Riverview Farms, 60 miles south of Chattanooga in Ranger, Ga., which will naturally taste different from the Indiana corn used in the present product.

Meanwhile, at the micro-distillery, McCracken is experimenting with other mash bills. He likes using the traditional bourbon requirement of at least 51 percent corn in the mash, but on that corn “canvas,” as he calls it, he will paint with some techniques he learned while brewing beer.

“If there is one thing I’d like to translate from my time in brewing to distilling, it’s utilizing the myriad malted grains that I’ve come to know and love,” McCracken says, adding that he is experimenting with “fuller flavored caramel malts, toasted malts, roasted malts and smoked malts.”

He concludes, “I think this will give us a lot of complexity in our finished spirit that hopefully people will appreciate. Because I know we do."

Chattanooga Whiskey has come a long way in its quest to bring whiskey to the people. And it’s still got a ways to go before it can truly claim to have brought distilling back to Chattanooga. Piersant doesn’t seem to be too worried about it, though. Maybe that’s because he knows he’s done something much more important than opening Chattanooga’s first fully operational distillery since Prohibition; he’s proven that if you rally people around an idea, something that everyone believes in, you can make the change you want. And right now, he’s OK with that.

Because he knows that the story of Chattanooga Whiskey isn’t over, not by a long shot.